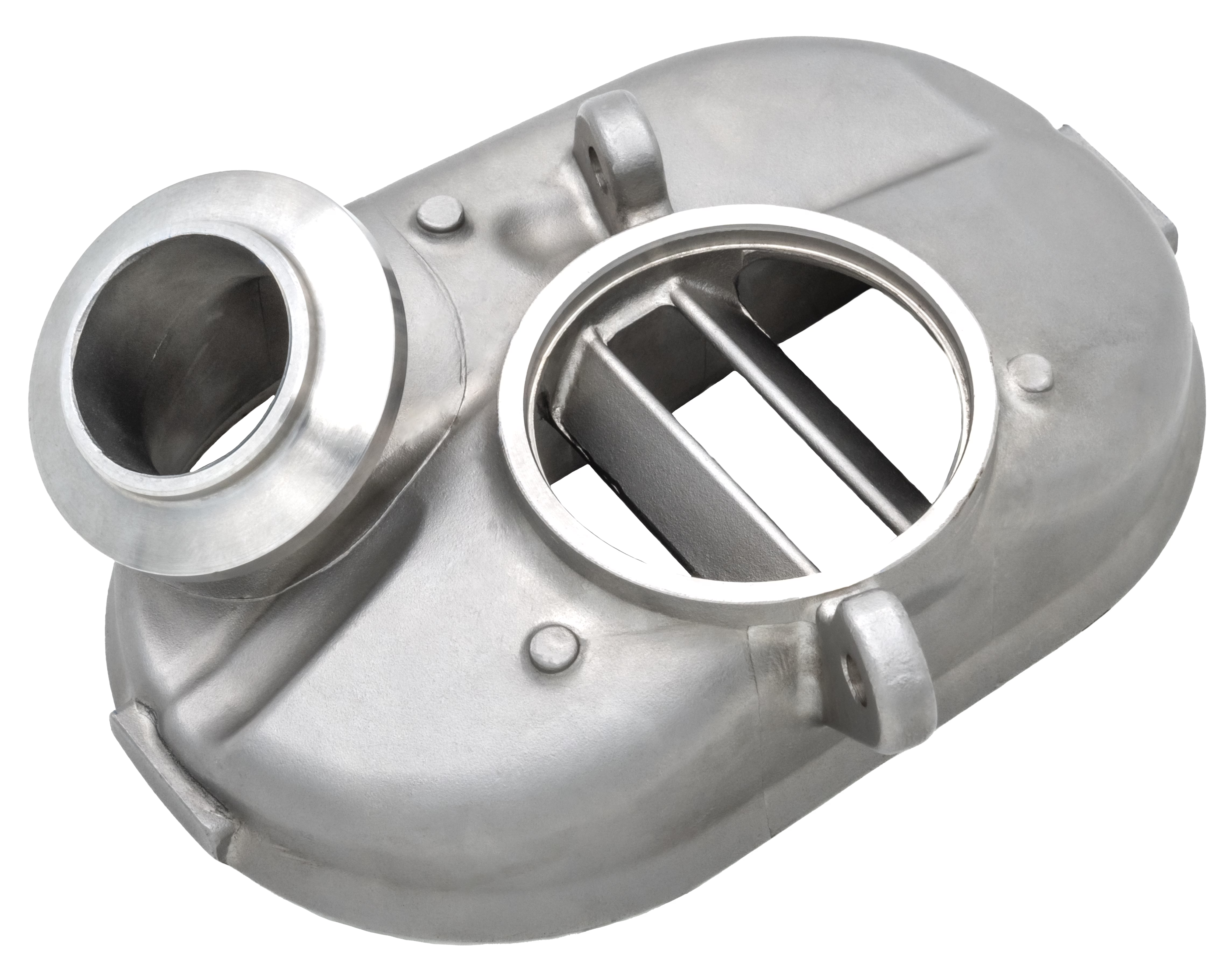

What Is Casting?

Casting is a manufacturing process where liquid material, typically metal, is poured into a mold that contains a hollow cavity of the desired shape, and then allowed to solidify. Once solidified, the workpiece is removed from the mold to undergo further processing if needed. This process is particularly beneficial for creating complex parts with intricate details and is widely used across various industries, including automotive, aerospace, and industrial machinery.

Comprehensive Casting Capabilities

Seglian offers a comprehensive range of casting processes for both ferrous and non-ferrous metals, ensuring precision and flexibility. Our capabilities include sand casting for large, complex parts, gravity die casting for non-ferrous metals, pressure die casting for high-volume detailed parts, and investment casting for intricate components. We also provide plaster casting for smooth finishes, centrifugal casting for cylindrical parts, lost-foam casting for complex shapes, vacuum casting to reduce porosity, and shell molding for high-precision applications. Our material expertise spans iron, stainless steel, aluminum, bronze, brass, zinc, and high-performance alloys, tailored to your needs.

Why Choose Seglian for Your Casting Needs?

Our comprehensive approach to casting, combined with our expertise in machining and value-added services, makes us the ideal partner for your manufacturing needs. We manage quality at every stage of the process, ensuring that your parts are delivered on time, within budget, and to the highest standards.