Accelerating Low-Emissions Manufacturing: How Seglian Facilitated a Rapid Transition from Europe to North America

In the fast-paced automotive industry, meeting stringent low-emissions standards is crucial. When a leading emission control products manufacturer needed to relocate production from Europe to North America, they turned to Seglian for support. Faced with tight deadlines and complex manufacturing requirements, Seglian’s expertise in supply chain management and precision manufacturing made the transition seamless and successful.

Meeting Stringent Emission Standards with Precision Manufacturing

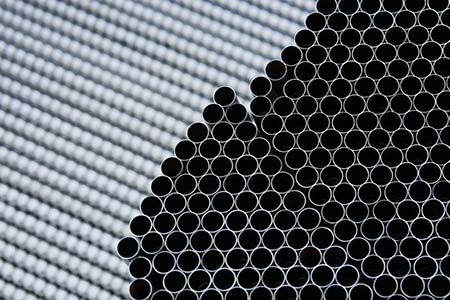

The manufacturer, focused on low-emission vehicle components, recently acquired a UK-based exhaust gas recirculator (EGR) manufacturer. With new U.S. diesel engine emission regulations in place, relocating production to Mexico became essential. Seglian was tasked with ensuring that three critical components—investment cast headers, precision gas tubes, and assembled housings—were produced, PPAP-approved, and delivered within an aggressive timeline.

Innovative Solutions for Precision Tubes and Case Assemblies

Seglian’s established network allowed us to quickly address the complex requirements of this project. For precision gas tubes, we partnered with a manufacturer whose existing capabilities matched the project’s stringent needs, enhancing their processes and meeting the six-month deadline. For case assemblies, Seglian worked with a supplier of stainless steel tubing, adding specialized machinery and submitting the PPAP ahead of schedule. As the project advanced, custom-designed machinery improved product efficiency, underscoring Seglian’s commitment to innovation.

Delivering Results: On-Time Production and Seamless Integration

Seglian’s comprehensive approach to supply chain management enabled the customer to transition production to North America in record time. The project met all deadlines, received PPAP approval, and began production on budget. Today, Seglian continues to support the manufacturer with high-quality products and innovative solutions that keep them ahead in the market.